Auditing project scope

The project scope was to do 2nd party audits for all system and manufacturing process audits in the organization. The audits were done based on the ISO 9001:2015 and IATF 16949:2016 requirements. In the scope was: Global Supply Chain Management, HR, Management with IT and Finance, Manufacturing Engineering with Maintenance, Logistics, Operations, Product Engineering, Quality Assurance and Launch Management according to Quality Management System processes in Borg Warner. Additionally in auditing project scope there were five VDA 6.3 manufacturing process audits in the scope P2 to P7 performed.

Targets

The target was to execute all internal audits in Borg Warner according to annual auditing program for all defined processes. The idea was also to have a perspective from external auditor for identifying opportunities for improvements for Quality Management System. At the end the goal was to use audit reports as an evidence of meeting auditing requirements. Also the goal was to pass successfully the IATF 16949:2016 3rd party audit.

Major Milestones:

– Reviewing documented information prior to audit.

– Some of the processes were defined in process maps as “mega-processes” – planning of the resources was crucial for resource availability.

– Execution of system process audits.

– Execution of manufacturing process audits according to VDA 6.3 in the scope P5-P7. (One audit was performed as a portion of VW self-assessment).

– Execution of manufacturing process audits according to VDA 6.3 in the scope P2-P4.

– Issuing individual reporting per each audited process with reporting on (not) meeting the Customer Specific Requirements.

Value added for the customer

Reporting

– 14 audit reports were issued where also opportunities for improvements were stated.

QMS specialist support

– Meeting the requirements of the audit program in QMS.

Resources constraints

– Independent auditor was assured in all processes with right competencies.

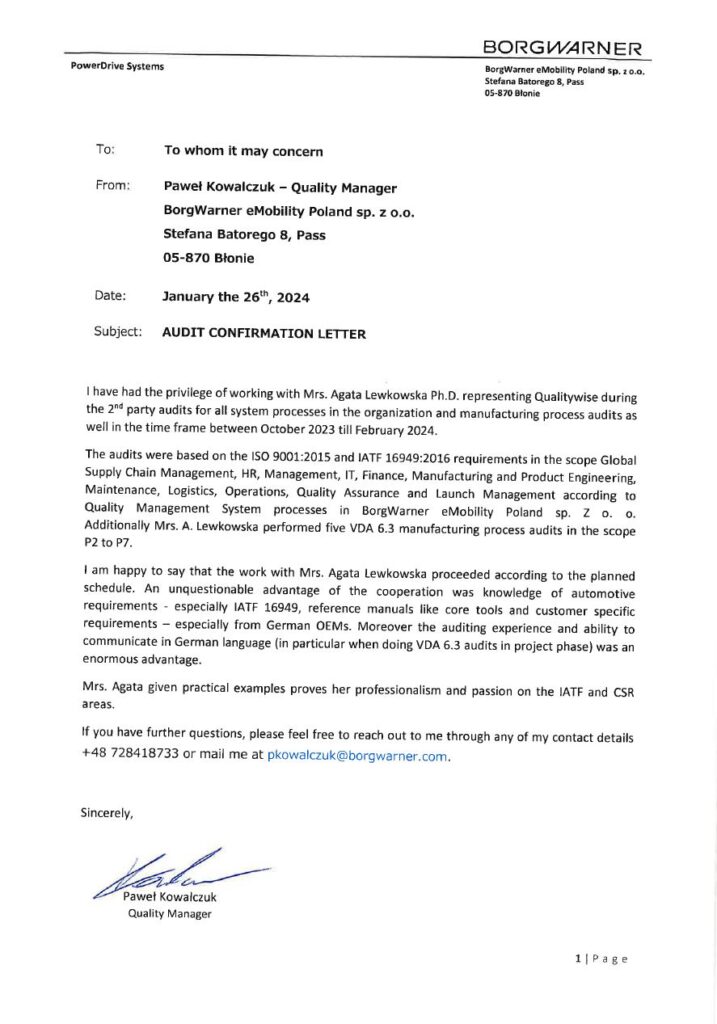

References from auditing project