In a competitive manufacturing environment, understanding the true cost of poor quality (COPQ) is important for any organization striving for long-term success. The cost of poor quality is often underestimated, but it represents a significant portion of a company’s overall expenditure. Reducing COPQ not only enhances profitability but also strengthens the organization’s reputation, improves customer satisfaction, and fosters a culture of continuous improvement. So all of it is supported by QMS requirements in IATF 16949.

What is the Cost of Poor Quality?

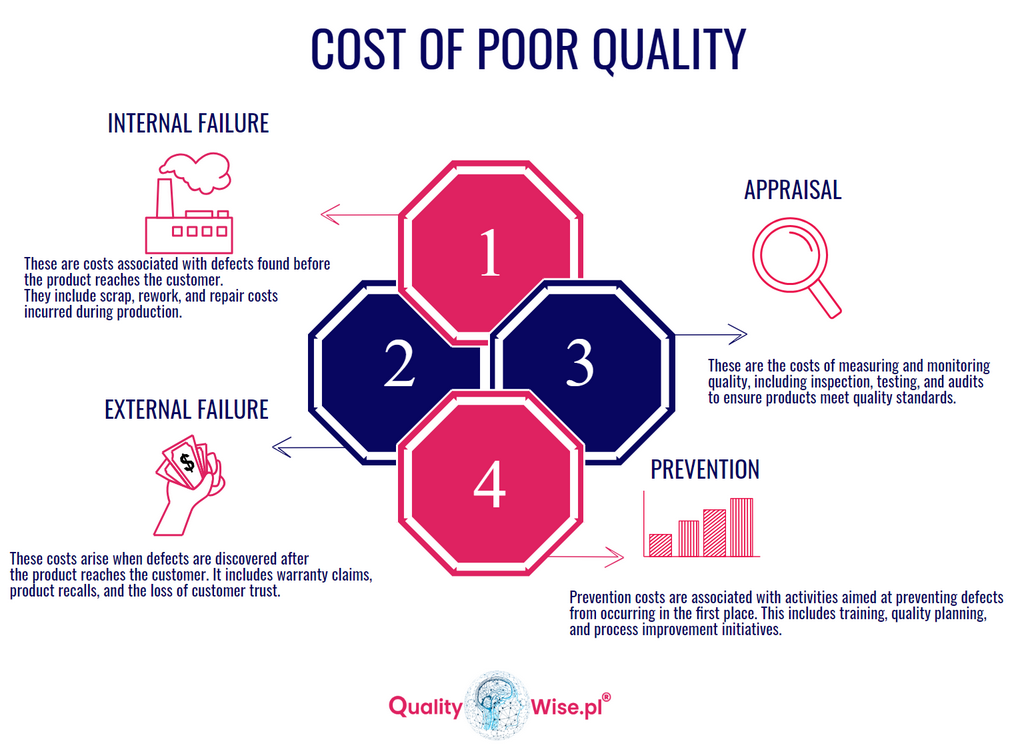

The term “Cost of Poor Quality” refers to the total cost incurred due to the failure to meet quality standards. This includes both internal and external costs and can significantly affect the overall financial health of a business. COPQ can be broken down into four main categories:

How Much Does Poor Quality Cost Your Business?

While the answer can vary greatly from one company to another, studies suggest that businesses lose as much as 20% to 30% of their revenue due to poor quality.

The most glaring impact is on external failure costs, which can tarnish a brand’s reputation and lead to lost customers. According to our industry experience, organizations that do not actively manage quality can expect significant costs tied to rework, warranty claims, and product returns. In fact, external failures can cost a company several times more than internal failures because they involve both direct costs and indirect impacts like brand damage and customer churn.

Why Is COPQ Often Overlooked?

Many companies overlook the true cost of poor quality because these costs are not always immediately visible on financial statements. Internal failures, such as rework and scrap, might seem like a normal part of the manufacturing process. But these inefficiencies add up over time. Additionally, companies tend to focus on external factors like production schedules and materials costs, while failing to account for the intangible but significant costs of poor product quality. This often results in businesses missing opportunities for improvement and growth.

How to Calculate the Cost of Poor Quality?

To calculate COPQ, companies need to track both direct and indirect costs related to quality issues. The formula is simple but effective:

COPQ = Internal Failure Costs + External Failure Costs + Appraisal Costs + Prevention Costs

However, calculating COPQ is not just about adding up numbers; it’s also about understanding the strategic impact of each category. For example, high appraisal costs may indicate a lack of process control. At the same time, high external failure costs may suggest poor product design or inadequate testing before release.

How to Reduce the Cost of Poor Quality?

- Focus on Prevention

One of the most effective ways to reduce COPQ is to invest in prevention. This can involve improving the design process, implementing stronger supplier management programs, and investing in employee training. Applying problem solving is post reaction – too late! - Leverage Continuous Improvement Tools

Implementing tools like Six Sigma, Lean, and Total Quality Management (TQM) can help identify and eliminate sources of waste and defects. These methodologies focus on continuous improvement and can help reduce both internal and external failure costs. - Incorporate Quality at the Source

Instead of relying solely on post-production inspection and testing, encourage employees at all levels to take ownership of quality. This approach—known as quality at the source—helps catch defects early in the process. It prevents costly rework and ensures that customers receive only the best products. - Use Data to Drive Decisions

Quality management systems (QMS) and data analytics can provide valuable insights into your manufacturing processes. By using data to identify trends and areas of concern, businesses can take proactive measures. Thus, it improves quality and reduces COPQ.

Now, put yourself in automotive OEM shoes…

… who, for example, is facing extensive warranty costs due to defects in its components. These defects lead to numerous returns, costly repairs, and a tarnished brand reputation. By implementing a robust Quality Management System (QMS) and shifting focus toward preventive measures in the design phase, the whole supply chain can reduce both the warranty costs and the number of defective units produced. Ultimately saving millions of dollars and restoring customer trust.

So what you should consider?

The first step is to track all related costs, including scrap, rework or repair, warranty claims, and customer returns. Implementing a robust QMS can help identify and categorize these costs, allowing you to calculate COPQ and pinpoint areas of improvement.

Lean manufacturing, Six Sigma, and the PDCA cycle are effective tools for reducing COPQ. These methodologies emphasize continuous improvement, waste reduction, and process optimization, all of which contribute to lowering COPQ.

Let’s sum up!

The Cost of Poor Quality affects your company’s margins, operational efficiency, and reputation. If you are not measuring and actively working towards reducing COPQ then eventually, your teams will lose morale. And you will lose future business opportunities.

Combating and preventing issues that drive the Cost of Poor Quality will lead to enhanced customer satisfaction. So no one should have any doubts that it’s worth it!

Do you feel your company could handle quality problems more effectively?

At QualityWise, we offer hands-on training in problem-solving techniques that will help you identify root causes and implement lasting solutions. Gain practical knowledge that will help you avoid costly mistakes. Improve the quality of your processes and click here for details.

Hope you found this article interesting. If you wish to receive our articles directly to your mailbox sign up to the newsletter!

Thank you for your presence.

For people who want to know more:

IATF 16949: 2016 Requirements for quality management systems in serial production and the production of spare parts in the automotive industry, 1st edition, 2016

All content on the qualitywise.pl website is a private interpretation of publicly available information. Any convergence of the described situations with people, organizations, companies is accidental. The content presented on the website qualitywise.pl does not represent the views of any companies or institutions.