It is not always possible to produce a product that complies with the requirements. It is natural in such a situation that the product cannot reach the customer in this form. And what if such a product could be “kept”, i.e. further processed to compliance with the requirements? Let’s see what the IATF 16949: 2016 standard says about rework and repair.

Rework and repair – what is it?

To talk about the requirements for repair and conversion in a quality management system, let’s see what these terms mean. Take a look at the ISO 9000:2015 standard for terminology.

Processing acting on a non-conforming product or service to make it compliant.

ISO 9000:2015 Quality management systems — Fundamentals and vocabulary, clause 3.12.8

Repair action against a non-conforming product or service, undertaken to adjust it for the intended use.

ISO 9000:2015 Quality management systems — Fundamentals and vocabulary, clause 3.12.9

What requirements can we find in the quality management system according to IATF 16949?

As repair and modification are completely different concepts, despite a certain similarity, also in the IATF 16949: 2016 standard we find separate requirements for each of them, i.e .:

• point 8.7.1.4 concerns control of reworked product,

• clause 8.7.1.5 concerns control of repaired product.

Let’s see what the requirements for each of them are.

8.7.1.4 Control of reworked product

This point requires:

- Assess the risks before deciding to rework a product.

- Customer approval must be obtained prior to rework the product, if required by the customer.

- Document the approval process of rework according to the control plan to verify compliance with the original specifications.

- Instructions for disassembly or rework, including re-inspection and traceability, should be available and followed by appropriate personnel.

- Documented information on quantity, disposition, disposition date, and applicable traceability used should be kept.

8.7.1.5 Control of repaired product

This point requires:

- Assess the risks before deciding to repair the product.

- Obtain customer approval before commencing repair the product.

- Document the approval process for the repair activities as per the control plan or other relevant documented information.

- Instructions for disassembly or repair, including re-inspection and traceability, should be available and followed by appropriate personnel.

- Documented customer approval for a concession for the product being repaired must be obtained.

- Documented information on the quantity, disposition, disposition date, and applicable traceability used should be kept.

Rework and repair – where are the differences in requirements?

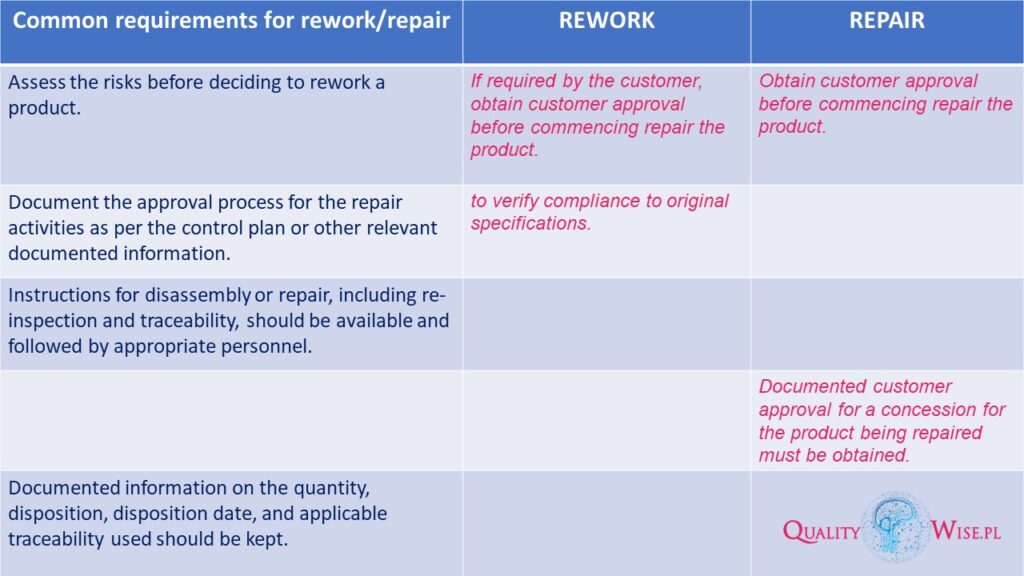

Reading the requirements for repair and conversion separately, it is difficult to spot the differences right away.

Below I have illustrated them for you.

Download the breakdown of requirements for rework and repair!

Hope you found the article interesting.

Thank you for your presence.

Agata Lewkowska Ph.D.

PS. If I can help you with quality management issues, please contact me. You may also join me in my private group on Facebook: ISO 9001 & IATF 16949 QualityWise Group.

For people who want to know more:

Knowledge must have a solid foundation in order to avoid information noise. Therefore, the article was based on the following literature:

IATF 16949: 2016 Requirements for quality management systems in serial production and the production of spare parts in the automotive industry, 1st edition, 2016

ISO 9000:2015 Quality management systems — Fundamentals and vocabulary

ISO 9001:2015 Quality management systems — Requirements

All content on the qualitywise.pl website is a private interpretation of publicly available information. Any convergence of the described situations with people, organizations, companies is accidental. The content presented on the website qualitywise.pl does not represent the views of any companies or institutions.