APQP according to AIAG

NEW 3rd edition 2024!

Too many requirements to meet?

Unfortunately, this is true, but knowing the requirements allows you to implement them effectively!

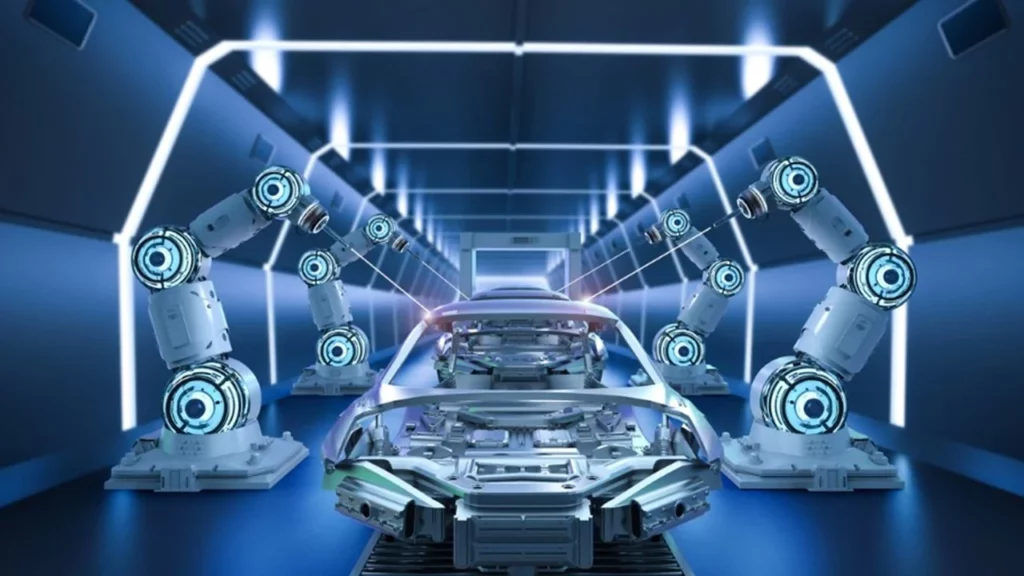

The automotive industry is a demanding industry: it is necessary to ensure “high” product quality with on-time delivery, while focusing on continuous improvement and minimizing errors and losses throughout the supply chain. All this to ensure high competitiveness. Therefore, in order to meet the requirements, car manufacturers require their suppliers to meet the requirements of the IATF 16949 standard, known before its new edition in 2016 as ISO/TS 16949. Learn more about this standard in our article IATF 16949 – what can your organization gain from this standard?

Training Program Highlights

- Basic principles of the quality management system in the automotive industry and their influences on project management – sources of requirements: the requirement of ISO 9001, IATF 16949, key quality methods – core tools, specific customer requirements, CSR (Customer Specific Requirements), Quality management system requirements in accordance with ISO 9001 and IATF 16949 regarding design and development,

- Assumptions of the Advanced Product Quality Planning (APQP) methodology

- Discussion of the individual stages of APQP and the project simulation as practical exercises during the training:

- project planning,

- product design,

- process design,

- product and process validation,

- production and feedback,

- Characteristics of the basic issues related to the individual stages of APQP, in particular:

- special characteristics

- Flow chart – FMEA – Control Plan

- work instructions

- Benchmarking

- Error/ mistake proofing

- DFM/DFA

- QFD

- DoE

- Gate checklists

- APQP 11 checklists.

Training objectives

- Presentation of the context of requirements for project management and approval of products and processes for serial production in the quality management system according to ISO 9001 and IATF 16949.

- Presentation of advanced management of product implementation projects for production in an automotive industry company according to the requirements of the APQP (Advanced Product Quality Planning) manual.

- Presentation of the changes from 2nd edition to 3rd edition in 2024.

Target Audience

- Persons leading new product implementation projects.

- Quality engineers, quality specialists, employees of the quality department,

- department owners/owners of key processes related to the implementation of new products for serial production,

- constructors, technologists,

- internal auditors, supplier auditors (first and second party).

Participant Benefits

During the training, the participant will learn:

- efficient project management according to the APQP methodology in accordance with individual stages,

- properly identify customer needs and requirements when implementing new projects,

- prepare for certification, recertification, control and customer audits in the automotive industry,

- what techniques and tools are required,

- what are the responsibilities of individual participants in the project and the principles of group work (interdisciplinary teams).

Organizational Benefits

- A competent employee who knows the requirements of the automotive industry

- Can use knowledge in practice

- Meeting the requirements during the audit

Qualification confirmation

E-certificate

Training duration

2 days x 7 hours

Training price

In order to get an offer please send a request to: contact@qualitywise.pl.

Documents

Terms and conditions you will find here.

Contact

For additional questions, other training dates or a dedicated training offer for your company, please contact Qualitywise®!