In May 2024, the new standard VDA 6.8 – Supply Chain Process Audit was introduced. Developed by the German Association of the Automotive Industry (VDA) and officially published in December 2024, this standard addresses the growing need for standardization and optimization across the entire automotive supply chain.

For many organizations operating in the automotive industry, it is still a relatively little-known document. Nevertheless, it is quickly gaining importance in relations with OEMs and Tier 1 customers.

What is VDA 6.8?

VDA 6.8 is a new VDA-QMC standard specifically designed for process audits within the supply chain. It focuses on logistics areas – planning, material flow management, supply risk control, and integration of quality requirements throughout the chain.

An internal assessment of compliance with VDA 6.8 is a fundamental element of effective quality management of logistics processes in the automotive industry. A systematic approach to self-assessment not only prepares the organization for external audits but also builds the foundation for continuous improvement and optimization of the supply chain.

How does it differ from VDA 6.3 and why are both standards complementary?

Until now, VDA 6.3 audits focused on production processes and the preceding project management phases. However, practice has shown that many quality issues originate not in production, but in logistics and supply chain management.

VDA 6.8 fills the critical gap created after the removal of Chapter 8 on services from VDA 6.3:2023. It concentrates exclusively on supply chain processes, eliminating production and development aspects, which allows for a more precise evaluation of logistics activities.

The main goal is to minimize risks across the supply chain and establish a global standard, eliminating the need to adapt to diverse customer-specific requirements.

Therefore, VDA 6.8 was developed as a complementary tool, enabling OEMs as well as Tier 1 and Tier 2 suppliers to assess the maturity and reliability of supply chain processes.

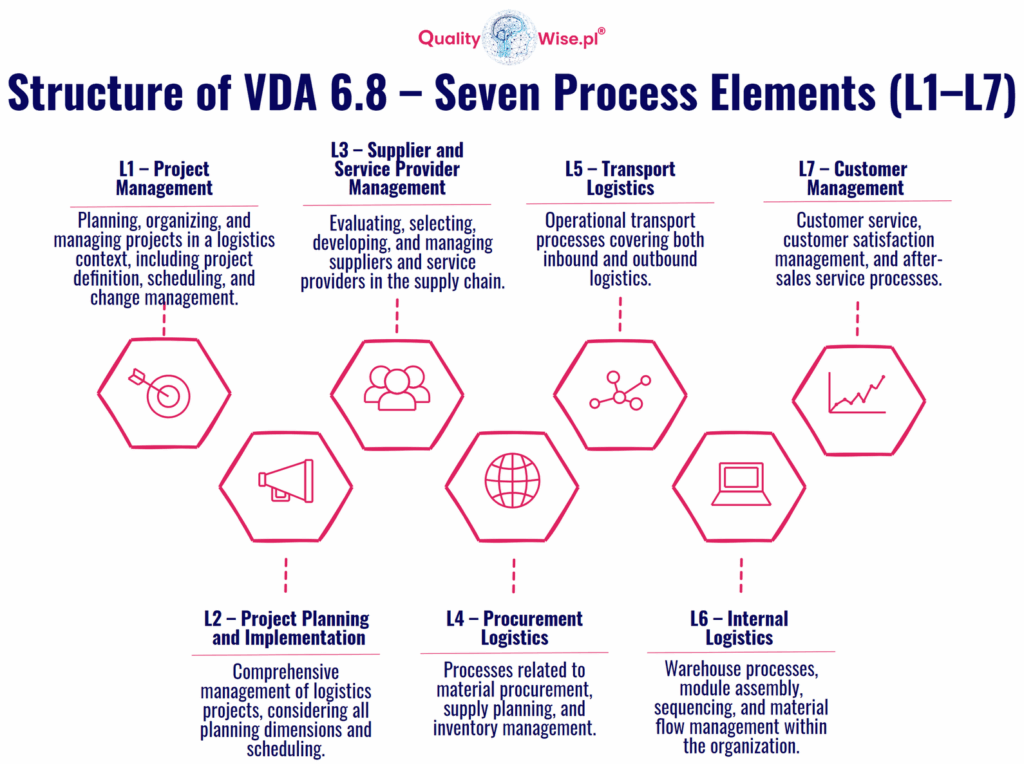

Structure of VDA 6.8 – Seven Process Elements (L1–L7)

The VDA 6.8 standard covers seven key process elements, which can be audited either comprehensively or modularly:

- L1 – Project Management

Covers planning, organizing, and managing projects in a logistics context, including project definition, scheduling, and change management. - L2 – Project Planning and Implementation

Comprehensive management of logistics projects, considering all planning dimensions and scheduling. - L3 – Supplier and Service Provider Management

Processes for evaluating, selecting, developing, and managing suppliers and service providers in the supply chain. - L4 – Procurement Logistics

Processes related to material procurement, supply planning, and inventory management. - L5 – Transport Logistics

Operational transport processes covering both inbound and outbound logistics. - L6 – Internal Logistics

Warehouse processes, module assembly, sequencing, and material flow management within the organization. - L7 – Customer Management

Customer service, customer satisfaction management, and after-sales service processes.

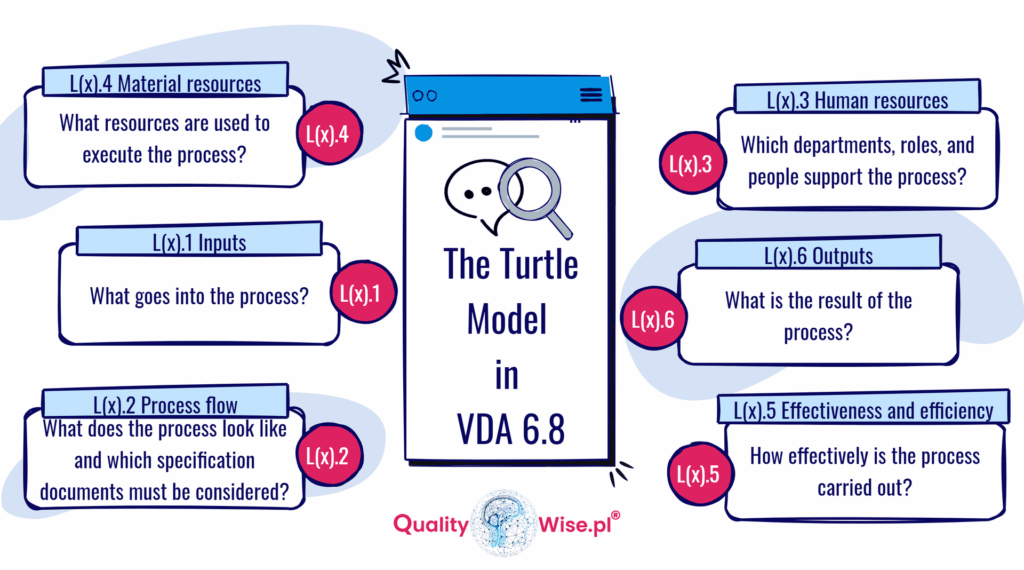

Turtle Model in VDA 6.8

The standard uses the Turtle Model as the structural basis for each process element. It defines six key questions for every process:

- L(x).1 Inputs: What goes into the process?

- L(x).2 Process flow: What does the process look like and which specification documents must be considered?

- L(x).3 Human resources: Which departments, roles, and people support the process?

- L(x).4 Material resources: What resources are used to execute the process?

- L(x).5 Effectiveness and efficiency: How effectively is the process carried out?

- L(x).6 Outputs: What is the result of the process?

Evaluation and Classification System

VDA 6.8 retains the A, B, C ratings known from VDA 6.3 for the overall audit score:

- Class A ( > 90%) – able to meet quality requirements

- Class B (80–90%) – able to meet quality requirements to some extent

- Class C (< 80%) – not able to meet quality requirements

The standard also applies the downgrading rules, just like VDA 6.3.

Each question is scored on a 10–8–6–4–0 scale:

- 10 points – fully compliant, no deviations

- 8 points – largely compliant (++)

- 6 points – compliant (+)

- 4 points – partially compliant (–)

- 0 points – not compliant (––)

Starred questions (*) highlight critical issues for supply chain security and functioning. Their evaluation can trigger an additional downgrade of the overall score.

Self-Assessment Possibility

VDA 6.8 introduces a self-assessment element through a potential analysis based on starred questions. This allows organizations to perform an initial readiness check before undergoing a formal audit.

Question to VDA 6.3 auditors:

Do you already see the similarities between VDA 6.8 and VDA 6.3?

Integration with Global MMOG/LE and Contemporary Requirements

One of the key features of VDA 6.8 is its full integration with Global MMOG/LE (Materials Management Operations Guideline/Logistics Evaluation). This creates a basis for mutual recognition of audit results between VDA organizations and Odette/AIAG.

The standard also reflects current requirements such as:

- Information security and cybersecurity in logistics processes

- ESG (Environmental, Social, Governance) requirements

- Regulatory compliance with national and international laws

Who is VDA 6.8 for?

From a supplier’s perspective, VDA 6.8 will be applied:

- to component and material suppliers, where supply stability and logistics are critical,

- in organizations acting as supply chain integrators, e.g., Tier 1 coordinating multiple Tier 2 suppliers,

- by OEMs, seeking greater transparency and control over risks across the supply chain.

If a company operates in logistics, purchasing, planning, and material management, it will be evaluated according to VDA 6.8.

Summary

The VDA 6.8 standard represents an evolution in auditing within the automotive industry, shifting the focus from traditional production processes to comprehensive supply chain management.

Its implementation is a strategic investment in the future, ensuring:

- Competitive advantage in a demanding automotive market

- Optimization of operational and process costs

- Increased customer and partner satisfaction

- Readiness for future industry challenges

Organizations that invest in VDA 6.8 implementation today will become tomorrow’s leaders in safe, efficient, and sustainable supply chain management in the automotive industry.

Is your organization ready to transform its logistics processes?

If you would like to know how your company would perform in a VDA 6.8 audit – or prepare step by step – Qualitywise supports organizations with training and audits in line with VDA 6.8. See VDA 6.8 training details.

👉 Contact us to learn more about how to prepare your supply chain for the new requirements.

Hope you found the article interesting.

Thank you for your presence.

For people who want to know more:

Volume 6.8 Supply Chain Process Audit, 1st Edition, December 2024

All content on the qualitywise.pl website is a private interpretation of publicly available information. Any convergence of the described situations with people, organizations, companies is accidental. The content presented on the website qualitywise.pl does not represent the views of any companies or institutions.