How do you effectively get a person to understand and execute a task? In Automotive Manufacturing, many OEM’s use a method called Training Within Industry (TWI).

TWI was developed in the 1940s in the United States as a rapid program to teach non-skilled workers to do the work millions of people used to do before they were drafted into the military. The skills gap needed to be closed to be able to continue domestic production as well as ramp up military production to sustain the war effort.

When the war ended and life resumed as normal in the US, the Japanese adopted this program and still use it today! See Toyota or Nissan…

Training Within Industry – what is it?

In simple terms, the best method to teach the job.

TWI is an interactive method to teach cyclic work to untrained people. It focuses on the materials used, equipment to perform the task and standard instructions (Operating Procedures).

In this article, we will explore how to use TWI for effective training and verification of a trainee’s understanding.

How do you train a person?

First, it’s important to understand the learning style of the trainee. What does this mean?

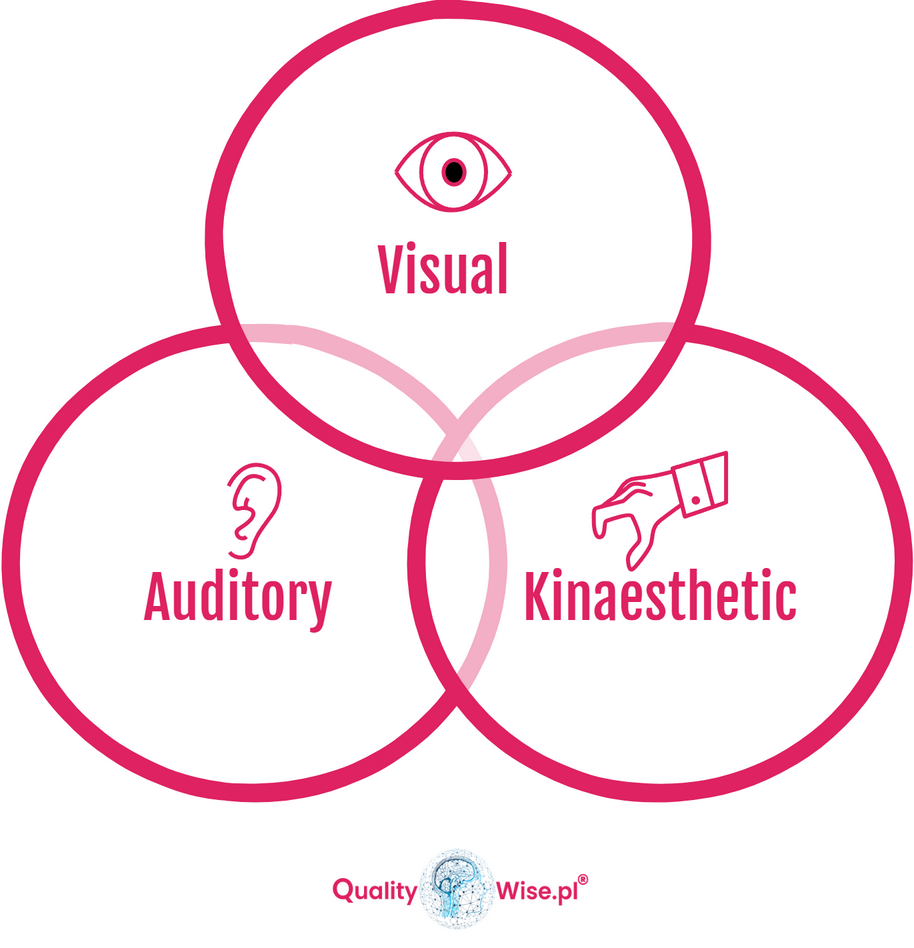

The VAK model is a form of learning signed by Walter Burke Barbe and developed by Neil Fleming in the early 1900’s.

- Visual Learners – absorb information by sight.

- Auditory Learners – absorb information by sound.

- Kinaesthetic Learners – absorb information by moving.

Most people find it easier to learn using one style, but the most effective way is to combine two types.

TWI – The 3-Step Method

Different OEM’s use different variations of this teaching method; today, we are going to outline the 3-Step Method.

- Explain the Operation.

- Explain what tasks are to be conducted.

- Check how much knowledge the trainee has about the operation.

- Explain the importance of the operation.

- Explain the materials, tools and equipment that are used.

This stage is key to reassuring the trainee and highlighting the Main Steps and Key Points of the Operation.

- Demonstrate the Operation

- Demonstrate the operation.

- Have the trainees perform the operation under supervision.

- Correct any errors and feedback to the Trainee.

- Have the Trainee perform the Operation

- Confirm who the trainee should speak to if they have any issues.

- Perform frequent Job observations.

- Encourage trainees to ask questions.

Training Within Industry Training Materials

In the context of Shop Floor work (Gemba),what are the important training materials to ensure that the trainee follows the process and is trained to the correct level?

Enter Standard Operations…

Standard Operations (Work Instructions) ensure Safety, Quality and Efficiency of the task. They are created with the input of several functions within a company, such as but not limited to:

- Manufacturing (Production) Engineering.

- Health & Safety

- Quality.

- Production.

- Material Planning & Logistics.

- Design Engineering.

It’s important to create, review and update Standard Operating Procedures whenever there is a change in the design or process, including non-conformances.

Training Within Industry in IATF 16949:2016

TWI is not specified in IATF 16949 directly, but its principles are highlighted:

Clause 7.2.2 : Competence – On-the-job training:

Any individual who assumes new or modified responsibilities that impact compliance with quality, internal, regulatory, or legislative requirements must receive the following requirements are to be considered:

- Training of Contract or Agency Personnel.

- Following Customer Requirements.

- Those who can impact Quality must be aware of the effects on the Customer.

Let’s sum up!

Consider assessing your current training methods and adopting Training Within Industry. Thus your organization can ensure your personnel conduct tasks in a safe and quality-conscious way. When they have doubts, concerns or questions, TWI encourages them to stop what they are doing. Also to escalate to their assigned contact according to reaction plan. TWI ensure standardisation, continuous improvement and customer satisfaction.

TWI is not mistake-proof! When critical operations or components affect meeting legal requirements, it is the Top Management’s responsibility to use Error Proofing to prevent the issues from happening.

Do you want to know more?

We invite you to the Training Within Industry course. We will explore the different types of Standard Operations, how to create them and how to consider Lean Principles to eliminate waste! Ask about the date.

Hope you found this article interesting. If you wish to receive our articles directly to your mailbox sign up to the newsletter!

Thank you for your presence.

For people who want to know more:

IATF 16949: 2016 Requirements for quality management systems in serial production and the production of spare parts in the automotive industry, 1st edition, 2016

All content on the qualitywise.pl website is a private interpretation of publicly available information. Any convergence of the described situations with people, organizations, companies is accidental. The content presented on the website qualitywise.pl does not represent the views of any companies or institutions.