Warranty… how many of us have needed to return an item which didn’t work the way we expected or was defective after a few months of use? Warranty Management is key to ensuring customer satisfaction, keeping a company’s reputation intact and protecting the manufacturer from customer abuse. In this article, we will explore how to manage warranty, key activities and recommendations to ensure you can robustly analyze claims and prevent them.

Warranty – what is it?

“A written guarantee, issued to the purchaser of an article by its manufacturer, promising to repair or replace it if necessary within a specified period of time.” – Oxford Languages

It means that under a specific agreement with the manufacturer, the customer has the right to claim the parts are defective when an issue is discovered within a warranty period.

Linking Warranty Management to Product Development

In many organizations, warranty management is treated as a reactive process that starts only when claims begin to appear. However, the most successful companies integrate warranty thinking into the very foundation of their product development and project management processes. Doing so leads to better product performance, fewer field failures, and stronger customer satisfaction.

Why Early Integration Matters

By considering warranty data and insights during the design and development phases, project teams can:

- Identify and mitigate risks before they become costly warranty issues.

- Leverage historical claim data to avoid repeating past design flaws.

- Validate new designs through targeted testing based on known failure modes.

- Reduce time-to-market by minimizing rework and late-stage changes.

- Improve cross-functional collaboration between engineering, quality, and customer service.

When warranty management is linked to project management from the start, even in APQP phase 1 “Plan and define program” we shall consider reliability of the product. This means teams can make data-driven decisions, develop more reliable products, and build long-term customer trust.

Warranty Management – Where to Start?

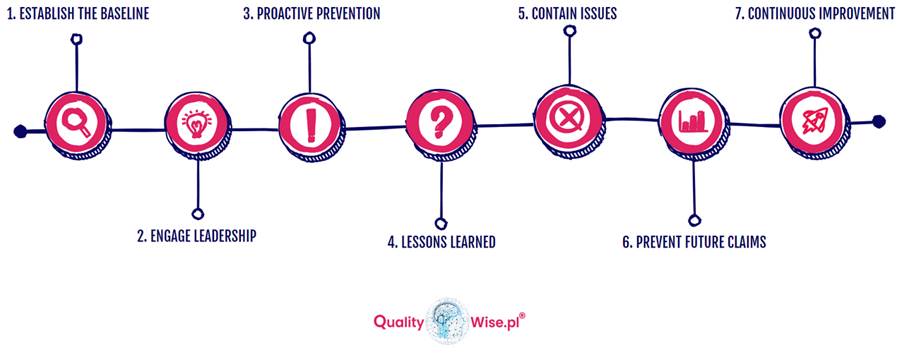

It can be daunting at first to consider a Warranty Process, especially if you find out your organization does not have one! The Automotive Industry Action Group has created a detailed guide, CQI-14 – Automotive Warranty Management: A Guideline to Industry Best Practices. Based on it wwe’ve highlighted the key steps to implementing or improving your Warranty Management Process.

1. Establish the Baseline

Assess the current Warranty Process in your company:

- Confirm if you have one.

- If you have one, does it favor the Customer?

- Does it effectively support Customer Satisfaction?

The actions highlighted here will help you identify gaps in the process. If your Warranty Policy is too generous, the adage “the customer is always right” springs to mind. It could result in reduced profit margins and affect your ability to be competitive, especially if your customer wants you to apply cost-downs to your product!

If your Warranty Policy does not support the customer, it can result in loss of future business and customer dissatisfaction.

2. Engage Leadership

Engaging leadership (or the customer if your organization is a supplier to an OEM) is imperative to driving Quality Improvement and Customer Satisfaction. Without leadershipbuy-in, it’s difficult to initiate warranty improvement strategies with organizational goals.

3. Proactive Prevention Activities

Implement preventative measures to reduce warranty claims by adopting Failure Modes & Effects Analysis, Control Plans, Problem Solving Methods and Error Proofing.

4. Implement Lessons Learned

Establish feedback loops from data generated by Warranty Claims. This data can be used in conjunction with Pareto Analysis and Problem Solving to improve product design and manufacturing methods. In Automotive manufacturing, the goal is to achieve continuous improvement through the sharing of knowledge and preventative actions!

5. Contain Warranty Issues

Ensuring your Warranty Management Process is effective in processing claims with clear problem descriptions is essential. It helps understanding the complaint with the suspected product. You should develop a strategy for rapid field response and containment.

6. Prevention of Future Warranty Claims

It’s critical to implement robust Permanent Corrective Actions through Error and Mistake Proofing to prevent further damage to your company’s reputation as well as financial penalties. We’d also like to recommend that you measure the effectiveness of your solutions to prevent recurrence.

7. Continuous Improvement

Monitoring your performance through time-bound periods such as 3-Months, 6-Months & 12-Months In Service is important to determine if your company’s product is meeting the market or customers expectations. It can be done by warranty KPIs and metrics:

- Warranty cost per unit sold

A core metric that reflects the financial impact of warranty issues over time. - Incidents per Thousand Vehicle (IPTV) How many warranty claims will happen during defined time period per 1000 vehicles

- First-year failure rate (FYFR)

Tracks the percentage of products failing within the warranty period—ideal for identifying early life-cycle problems. - Time to root cause (TTRC)

Measures how quickly warranty-related issues are diagnosed and resolved. - Repeat issue rate

Identifies how often the same failure reoccurs, showing whether corrective actions are effective.

Warranty management in IATF 16949:2016

It’s important to understand the link between Warranty, Customer Satisfaction and IATF 16949.

Clause 9.1.2.1 – Customer Satisfaction states:

The organization is to monitor customer satisfaction through assessing internal and external performance indicators. The performance indicators must be based on:

- Objective evidence.

- Customer disruptions.

- Field Returns.

- Recalls.

- Warranty Claims.

Clause 10.2.5 – Warranty Management Systems states:

If the organization is obligated to offer warranties for their products, they must establish a warranty management system. Including:

- Procedures for analysis returned parts for investigation.

- Instances where No Trouble Found (NTF) is found.

- If required by the Customer, the supplier must adopt their designated process.

Chapter 8.2 and 8.3 – Design and Development

It is crucial to not only recognize the customer requirements but also statutory and regulatory requirements connected to the specific market. In next chapters we developed some main markets to highlight basic requirements.

Let’s sum up!

Warranty management cannot be regarded as handling claims. The most successful companies don’t wait for problems to arise—they use warranty insights proactively to improve products and processes. By integrating warranty data into project management, design and development processes organizations can reduce failure rates, lower costs, and build greater customer trust.

Is your warranty management process adding value or just generating cost?

At Qualitywise.pl we help automotive and manufacturing organizations implement robust warranty management systems that support better design, stronger quality assurance, and continuous improvement. Contact us to discuss how we can support your team with Warranty Management according to AIAG CQI-14 training.

Hope you found this article interesting. If you wish to receive our articles directly to your mailbox sign up to the newsletter!

Thank you for your presence.

For people who want to know more:

CQI-14 – Automotive Warranty Management: A Guideline to Industry Best Practices

IATF 16949: 2016 Requirements for quality management systems in serial production and the production of spare parts in the automotive industry, 1st edition, 2016

All content on the qualitywise.pl website is a private interpretation of publicly available information. Any convergence of the described situations with people, organizations, companies is accidental. The content presented on the website qualitywise.pl does not represent the views of any companies or institutions.