In the past, suppliers often saw homologation as the final administrative step before product launch – a box to tick once design and validation were complete. Today, that mindset can cost you the project. OEMs and regulatory bodies have made type approval far more rigorous. The European Green Deal, UN ECE regulations, cybersecurity standards (UNECE R155/R156), and new safety requirements all place homologation at the heart of a supplier’s compliance strategy. For Tier 1 and Tier 2 suppliers, homologation is no longer to get certificates. It’s about market access, legal responsibility, and customer trust. If your component is not homologated, it will not leave the drawing board.

What Is Homologation (Type Approval)?

In simple terms, homologation -or type approval – is the process of certifying that a vehicle, system, or component meets all applicable legal and safety requirements before being sold or used in regulated markets.

It is the official authorization granted by an approval authority (such as KBA in Germany or VCA in the UK, NHTSA in USA) confirming that a product complies with specific technical regulations, most commonly the UNECE framework.

Homologation applies not only to complete vehicles but also to subsystems such as lighting, braking, emissions, or electric drive components—and increasingly, to software-controlled systems.

Not All Components Require Homologation

This distinction is often misunderstood. Certain parts, such as fasteners or purely decorative trims, are not subject to approval. However, any component influencing vehicle safety, environmental performance, or system functionality typically is. Understanding whether your product falls within the homologation scope is the first critical decision in every project.

Why Homologation Matters for Automotive Suppliers

Homologation is a strategic enabler, not merely a compliance formality. Let’s break down why it matters:

1. Market Access

Without homologation, a product cannot legally enter markets governed by EU, UK, or UNECE regulations. In other words, no certificate – no market. For global suppliers, this often means multiple homologation cycles adapted to regional legislation.

2. OEM Expectations

Vehicle manufacturers require evidence of homologation for every regulated component. They may include homologation milestones directly in the APQP timeline or Sourcing Agreements, making delays extremely costly.

3. Risk Management

Operating without homologation—or with outdated certificates—exposes suppliers to severe consequences:

- Recalls due to non-conforming parts,

- Penalties from regulatory bodies,

- Termination of supply contracts.

4. Reputation and Competitive Advantage

A valid approval demonstrates technical competence, regulatory awareness, and reliability. OEMs prefer working with suppliers who manage homologation proactively—it signals maturity and credibility.

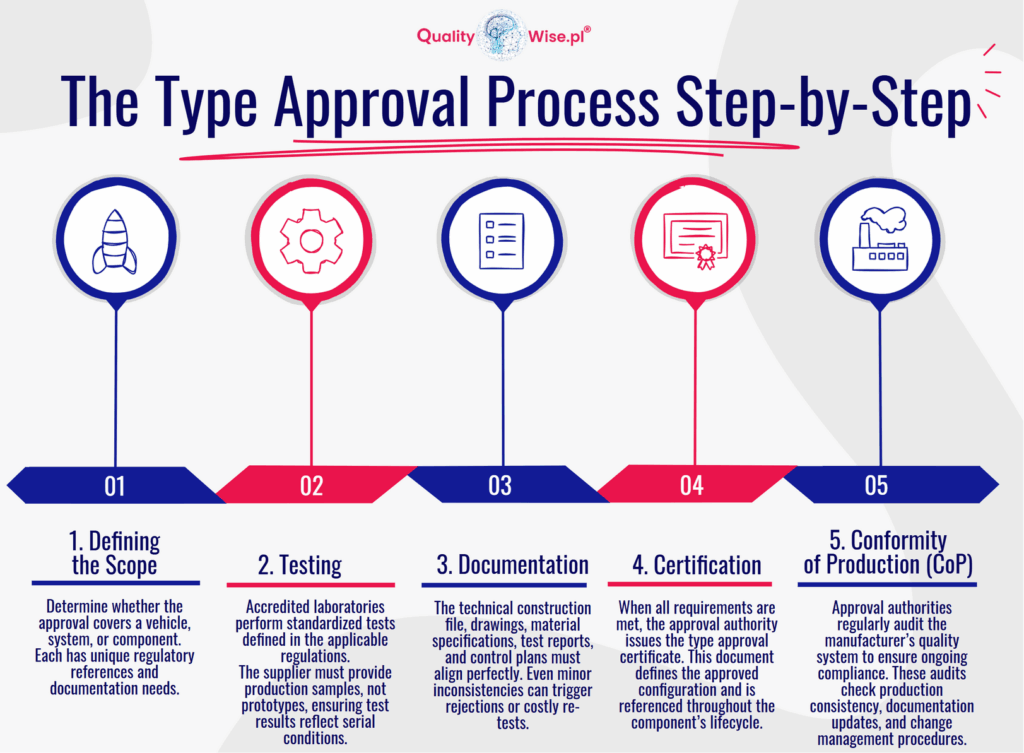

The Type Approval Process Step-by-Step

Although the details vary by region, the general sequence is consistent across markets.

1. Defining the Scope

Determine whether the approval covers a vehicle, system, or component.

Each has unique regulatory references and documentation needs. For example:

- UNECE R13 for braking systems,

- UNECE R48 for lighting installation,

- UNECE R100 for electric vehicle safety.

2. Testing

Accredited laboratories perform standardized tests defined in the applicable regulations. These can include mechanical durability, electromagnetic compatibility, or environmental performance. The supplier must provide production samples, not prototypes, ensuring test results reflect serial conditions.

3. Documentation

This is where many projects falter. The technical construction file, drawings, material specifications, test reports, and control plans must align perfectly. Even minor inconsistencies can trigger rejections or costly re-tests.

4. Certification

When all requirements are met, the approval authority issues the type approval certificate with an E-mark (e.g., E1 for Germany). This document defines the approved configuration and is referenced throughout the component’s lifecycle.

5. Conformity of Production (CoP)

Homologation is not a one-time event! Approval authorities regularly audit the manufacturer’s quality system to ensure ongoing compliance. These audits check production consistency, documentation updates, and change management procedures. Treat CoP like a customer audit—prepare evidence proactively, keep traceability clear, and involve your quality team early.

Homologation vs. Other Quality Certifications

Many suppliers confuse homologation with quality management system (QMS) certifications such as ISO 9001 or IATF 16949, or customer-specific approvals like PPAP.

| Type | Purpose | Issued By |

| Homologation | Legal approval for market entry | Government or authorized body |

| IATF 16949 | Quality management system standard | Accredited certification body |

| PPAP | Customer approval for production readiness | OEM or Tier 1 customer |

A component can successfully pass a PPAP but still be illegal to sell if it lacks homologation.

Understanding these distinctions prevents serious compliance gaps.

Common Challenges Suppliers Face

Even experienced automotive organizations struggle with homologation for several recurring reasons:

1. Late Involvement in the project management process

Homologation is often treated as an afterthought. When it’s not integrated into APQP, critical test planning, cost estimation, and timing are missed—causing launch delays or emergency testing.

2. Poor Documentation Control

Authorities require clear traceability from design to validation. Incomplete or inconsistent documentation leads to endless clarification requests and project fatigue.

3. Design and Process Changes

Implementing changes after certification—without notifying the approval authority—can invalidate the certificate.

This is especially common during cost-reduction projects or supplier resourcing changes.

4. Weak CoP Management

Many organizations underestimate the rigor of Conformity of Production audits.

Without stable processes, calibration control, and internal audits, the company risks suspension or withdrawal of approval.

5. Limited Knowledge Across Teams

Homologation responsibility often sits with a single specialist, leaving engineers, project managers, or quality staff unaware of their role in maintaining compliance. Homologation should be seen as a cross-functional process—not an isolated task for regulatory teams. Quality, engineering, purchasing, and project management must work hand in hand.

Best Practices for a Robust Homologation System

1. Integrate Homologation into Your QMS

Map homologation processes directly into your IATF 16949 system. Define clear ownership, document control procedures, and escalation paths for regulatory changes.

2. Include Homologation in project management

At QualityWise, we recommend treating homologation as a dedicated deliverable in the project management i.e. in Advanced Product Quality Planning (APQP) checklist. It ensures test planning, timing, and reporting are embedded early—long before the SOP date.

3. Strengthen Documentation Discipline

Adopt a structured document management system that keeps:

- Test reports,

- Certificates,

- Design revisions,

- Control plans,

all synchronized and version-controlled.

This reduces errors and accelerates responses to authority requests.

4. Train Cross-Functional Teams

Provide regular training for engineers, project managers, and auditors on homologation fundamentals. Awareness across departments builds resilience and reduces dependency on single experts.

5. Conduct Internal CoP Simulations

Run internal audits mirroring Conformity of Production requirements. Check sampling, traceability, and control of changes. Such simulations reveal weaknesses before the authority does.

6. Monitor Regulatory Updates

UNECE and local authorities frequently update regulations. Assign responsibility for tracking changes and assessing their impact on existing approvals. Non-compliance due to outdated knowledge can lead to unexpected production holds.

Homologation in the Era of Software and Electrification

The rise of electric vehicles (EVs) and software-defined architectures introduces new homologation challenges. Regulations such as UNECE R155 (Cybersecurity) and R156 (Software Update Management) extend type approval requirements beyond hardware to include digital lifecycle management.

This means your IT, cybersecurity, and engineering teams must now collaborate under the same compliance umbrella. Documentation must demonstrate not only product safety but also data integrity, secure updates, and change control throughout the vehicle’s life.

For many traditional mechanical suppliers, this represents a steep learning curve—but also an opportunity to strengthen capability and remain relevant in the evolving value chain.

Key Takeaways

- Homologation (type approval) is the legal gateway to selling vehicles and components.

- It requires early integration into APQP and the quality management system.

- Documentation, CoP control, and cross-functional training are essential success factors.

- Neglecting homologation risks delays, penalties, and loss of customer trust.

- When managed strategically, it becomes a competitive advantage that enhances your standing with OEMs.

Leading suppliers don’t see homologation as an obstacle. They see it as a strategic differentiator. By embedding approval processes into the company’s DNA, they achieve faster time-to-market, fewer disruptions during customer or authority audits, greater confidence from OEMs and Tier 1 partners. A well-managed homologation system reflects a culture of discipline, transparency, and continuous improvement—core principles of automotive quality.

How Qualitywise® Can Help

At Qualitywise®, we support automotive suppliers in building and improving homologation processes through:

- Training for engineers, quality professionals, and project managers on homologation fundamentals and CoP requirements.

- Consulting to integrate type approval processes into IATF 16949 and APQP frameworks.

- Documentation and readiness reviews before authority or OEM audits.

By treating homologation as a core element of your quality system, you ensure compliance, reduce risk, and position your company as a trusted partner in the global automotive supply chain.

👉 Ready to strengthen your homologation readiness?

Request a free 30-minute consultation. We’ll analyze your current situation, project scope, and customer requirements – and provide a practical roadmap tailored to your organization.

Hope you found the article interesting.

Thank you for your presence.

All content on the qualitywise.pl website is a private interpretation of publicly available information. Any convergence of the described situations with people, organizations, companies is accidental. The content presented on the website qualitywise.pl does not represent the views of any companies or institutions.