SPC-MSA according to AIAG

Can you truly make confident quality decisions

if you’re not sure whether your data is trustworthy?

In modern manufacturing, data drives everything — from process control to auditing to product conformity decisions. Yet the presence of data alone does not guarantee quality. To genuinely protect the customer, teams must understand how to assess process stability (SPC) and measurement system reliability (MSA) according to AIAG requirements. This training brings together two critical disciplines: Statistical Process Control and Measurement System Analysis, demonstrating how their correct application impacts process safety, decision-making accuracy, and the reduction of quality costs.

Training Program Highlights

SPC-MSA according to AIAG

- Quality management system requirements in accordance with ISO 9001:2015 and IATF 169491 for statistical process control and measurement systems analysis.

SPC:

- Statistical quality tools – IS0/TR 10017 standard.

- Basic statistical analysis of data (statistical description of variability).

- Sources of variation

- Random and systematic causes of variability, the concept of a stable (under control) and unstable (out of control) process.

- Statistical description of variability – determination and interpretation of descriptive parameters (mean, median, range, standard deviation, skewness, kurtosis, etc.), histogram construction (selection of the number of intervals), data distribution.

- Calculation and interpretation of process capability indicators (Cp, Cpk, Pp, Ppk).

- Shewhart process control charts.

- General principles of Shewhart’s control charts (three-sigma card, methods of card construction, adapting the card to the process).

- Construction of Shewart’s control charts for measurable characteristics – mean value and range chart, mean value and standard deviation chart, median and range chart, single observation chart and moving range).

- Calculation of process capability indicators Cp, Cpk based on control charts for measurable features.

- Control cards for attribute characteristics: fraction of non-compliant units p, number of non-compliant units, e.g. c-card, u-card.

- Examples, exercises.

MSA:

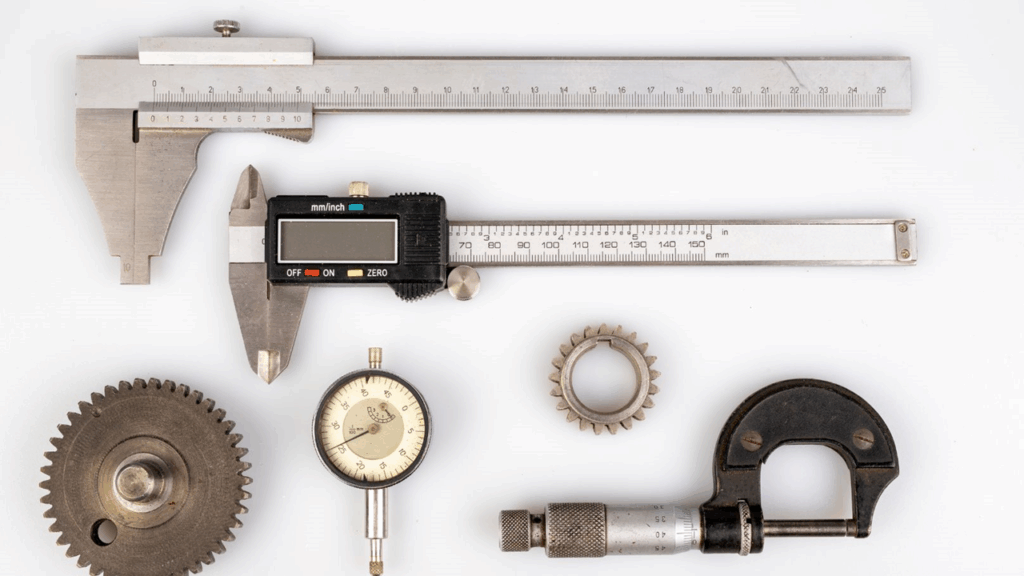

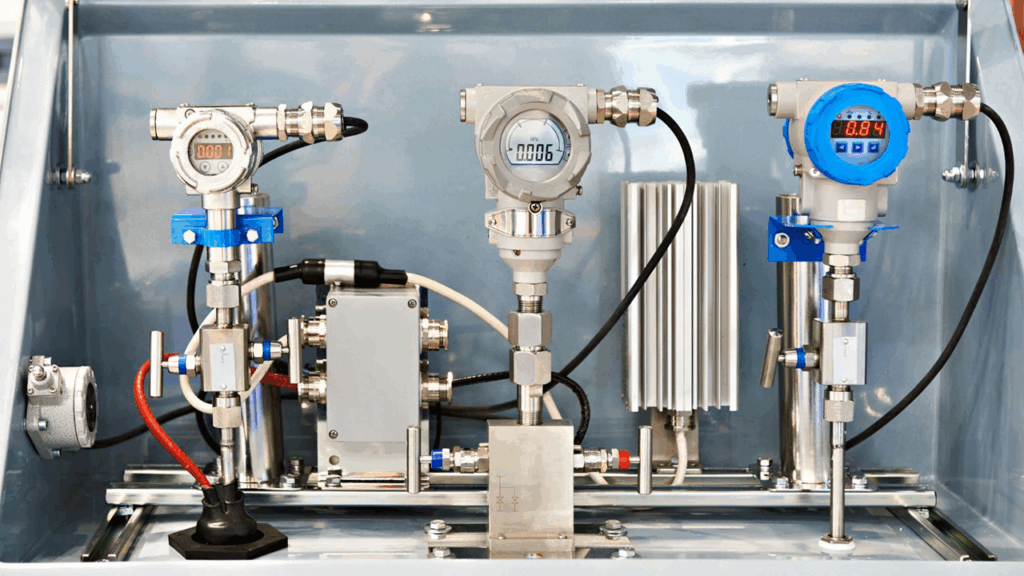

- Measurement, measurement error/uncertainty, measurement system, measurement process.

- Variation for a measurement process from instrument (EV), from operator (AV), from process i.e. part-to-part (PV), total variation (TV).

- Explanation of terms: precision, accuracy, resolution.

- Capability of measurement systems according to procedure 1, determination and interpretation of Cg, Cgk coefficients.

- Methods of assessing the measurement system with the influence of the operator and the instrument – procedure 2: the range method, the average range method ARM, analysis of variance (ANOVA).

- Methods of evaluating the measurement system without the influence of the operator – procedure 3.

- Assessment of the capability of measurement systems in case of an alternative characteristics: Signal detection method, Cross Table Method: operator-to-operator, operator-to-refference – determination and interpretation of Cohen’s kappa coefficient.

- Examples, exercises.

Training objectives

The objective of this course is to equip participants with practical skills in applying SPC and MSA methods in alignment with AIAG manuals. Participants will learn how to evaluate process capability, analyze data variation, and verify the reliability of measurement systems — enabling informed, data-driven quality decisions.

Target Audience

- persons responsible for the implementation, maintenance and improvement of SPC and MSA procedures,

- quality specialists, quality engineers, technologists,

- persons responsible for the quality of suppliers, employees of departments cooperating with the client,

- persons responsible for supervising measurement systems and it’s auditors.

Participant Benefits

After completing the training, participants will:

Understand how to use SPC to monitor processes and detect deviations before they escalate.

Be able to calculate and interpret Cp, Cpk, Pp, Ppk capability indices.

Evaluate process stability using control charts.

Understand the structure and stages of MSA in line with AIAG (GRR, Bias, Linearity, Stability).

Identify sources of measurement variation and define appropriate improvement actions.

Organizational Benefits

Organizations gain:

More stable processes with reduced unplanned quality deviations.

Improved decision-making based on reliable, repeatable measurement data.

Lower quality costs through predictive rather than reactive actions.

Easier compliance with customer-specific requirements and IATF 16949 audits.

Enhanced competencies in process control and measurement system evaluation.

Qualification confirmation

E-certificate

Training duration

2 days x 8 hours

Training price

In order to get an offer please send a request to: contact@qualitywise.pl.

Documents

Terms and conditions you will find here.

Contact

For additional questions, other training dates or a dedicated training offer for your company, please contact Qualitywise®!