IATF 16949 for Engineers

Too many requirements to meet?

Unfortunately, this is true, but knowing the requirements allows you

to meet them effectively!

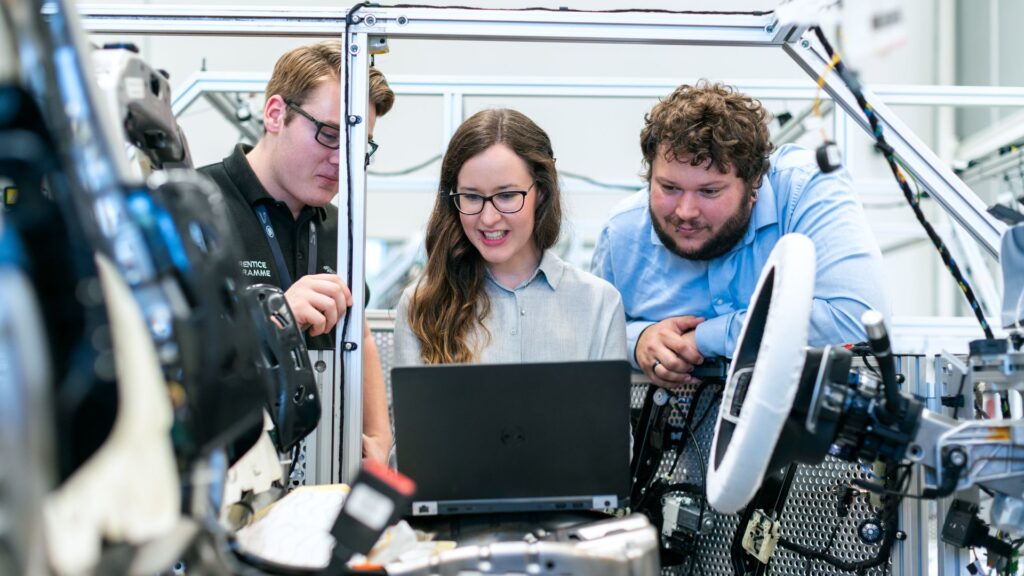

IATF 16949 is the globally recognized quality management standard for the automotive industry, focusing on defect prevention, continuous improvement, and waste reduction. Engineers play a crucial role in implementing these principles, ensuring that design, production, and process controls meet the highest quality standards. This training provides engineers with the knowledge and tools necessary to comply with IATF 16949 requirements and drive quality excellence in their organizations. Read more about IATF 16949.

Training Program Highlights

- The most important requirements of ISO 9001 and IATF 16949 applicable to the work of quality and process engineers.

- The role of engineers in the new launch process, including requirements that must be met in the implementation of advanced product quality planning (APQP),

- What requirements must be met to move from pre-series to series,

- Basic assumptions of Statistical Process Control (SPC),

- Guidelines for numerical and attribute analysis for measurement system analysis (MSA) – basic requirements,

- How to work with Potential Failure Mode and Effect Analysis (FMEA),

- FMEA for design (DFMEA) and process (PFMEA) – differences and interactions,

- Identifying special characteristics in PFMEA,

- Control Plan Requirements and Guidelines in the AIAG Control Plan Manual, Edition 1, effective March 2024,

- Control Plan Phases,

- Effective Use of the Control Plan with FMEA in the Everyday Work of the Engineer.

Training objectives

This training aims to equip engineers with the skills and knowledge needed to implement IATF 16949 effectively. By understanding core quality tools and risk management techniques, engineers will be able to enhance product quality, reduce defects, and ensure compliance with automotive industry standards.

Target Audience

- Design and Manufacturing Engineers

- Quality Engineers

- Process and Production Engineers

- Supplier Development Engineers

- Internal auditors.

Participant Benefits

- In-depth understanding of IATF 16949 requirements and their practical application.

- Enhanced ability to use core quality tools for process improvement.

- Improved problem-solving and risk assessment skills.

- Increased confidence in implementing engineering best practices for compliance.

Organizational Benefits

- Higher product quality and reliability, leading to increased customer satisfaction.

- Reduced production defects, rework, and waste.

- Stronger compliance with automotive industry requirements.

- Improved efficiency and cost savings through better process control.

Qualification confirmation

E-certificate

Training duration

2 days x 7 hours

Training price

In order to get an offer please send a request to: contact@qualitywise.pl.

Documents

Terms and conditions you will find here.

Contact

For additional questions, other training dates or a dedicated training offer for your company, please contact Qualitywise®!