Phone: +48 603 880 578 |

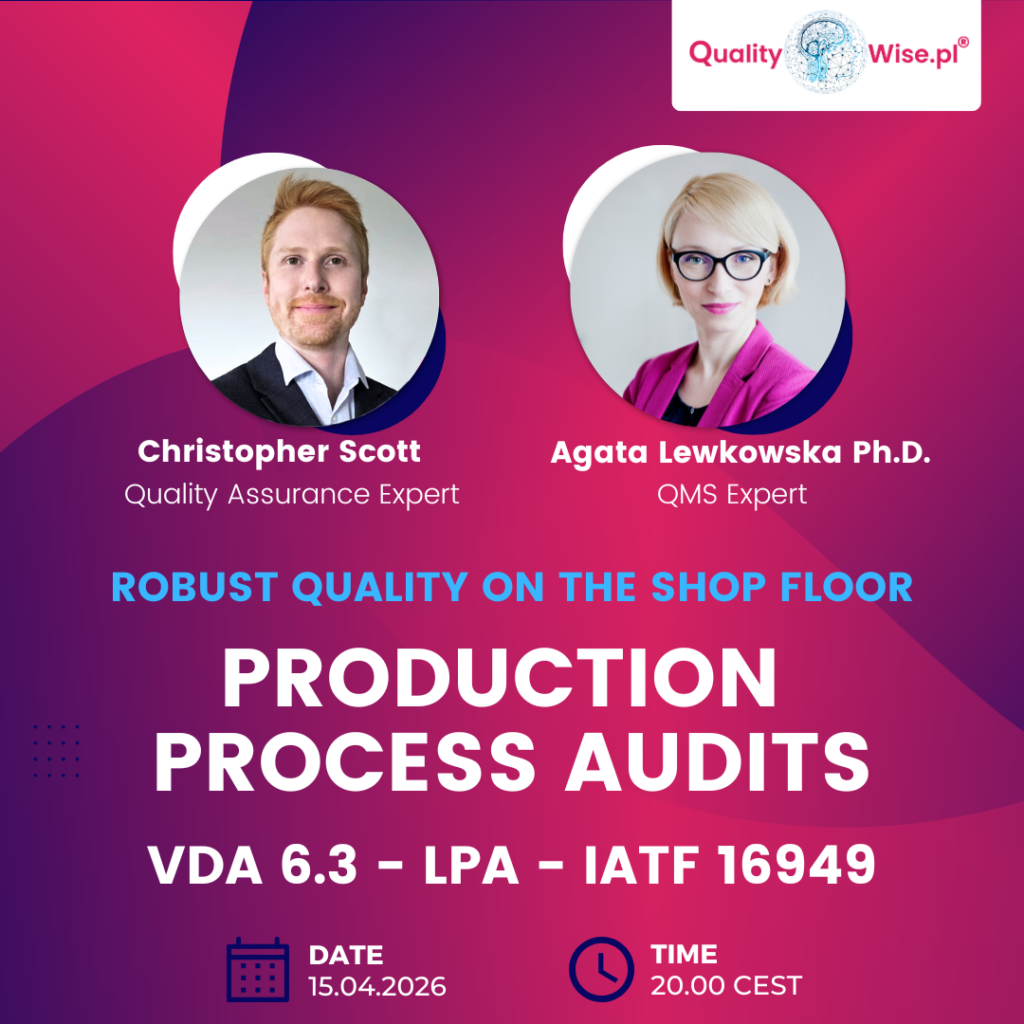

Email: contact@qualitywise.pl

Contact us!

Sign up for our webinar series:

A Five-Part Masterclass Series for Manufacturing & Automotive Quality Professionals

Join this exclusive webinar series and learn how to build strong, stable, and predictable quality directly where it matters most: in daily production, with your operators, your processes, and your data.

Throughout five strategically connected sessions, we show you how to transform your shop-floor routines into a robust quality ecosystem.

Free registration for BONUS materials.

Designed for both automotive and non-automotive manufacturers.

Practical. Actionable. Immediately implementable.

Whether you work in an IATF 16949, VDA, or ISO 9001 environment — or you simply want to benchmark against the highest industry standards — this masterclass series will give you clarity, structure, and tools.

What we cover:

Outcome:

You will leave with a structured daily start-up model that ensures quality from the first part.

What we cover:

Outcome:

You will know how to build a measurement system that prevents defects instead of only reporting them.

What we cover:

Outcome:

You will learn how to use audits as a proactive tool for quality assurance and risk reduction.

What we cover:

Outcome:

You will understand how to implement 8D as a real problem-solving process — not a template.

What we cover:

Outcome:

You gain a sustainable model for continuous process improvement and knowledge retention.

Everything is rooted in real plant experience — what works, what doesn’t, and why.

IATF 16949, AIAG Core Tools, VDA 6.3, LPA, CI — integrated into one flow.

Each webinar builds on the previous one – a complete approach to robust quality on the shop floor.

Every session includes actionable frameworks, checklists, and examples.

To receive the Certificate of Attendance for the Robust Quality on the Shop Floor webinar series, you must meet the following requirements:

Registration & Consent

You must be registered for our webinars and give consent to receive our communications/newsletters. Registered participants will receive bonus materials, including the webinar presentation slides.

Attendance Requirement

You must attend at least 4 out of the 5 webinars in the series.

Certificates will be issued only to participants who meet both conditions.

Register Now!

➡️ Register once — access all five sessions with links sent directly to your mailbox.

➡️ Live Q&A + replay available.

➡️ Get Certificate of completion.

Secure Your Spot in the Full 5-Part Series!

You can join:

✓ One webinar

✓ A selected set

✓ Or the full series (recommended for continuity and certificate)