SPC according to AIAG –

Statistical Process Control

Are your process data truly helping you prevent defects —

or are they only telling you what already went wrong?

SPC according to AIAG is one of the most powerful tools within the quality management system. When Statistical Process Control is implemented properly, it transforms organisations from merely detecting problems to anticipating and preventing them. This training provides a practical, industry-focused approach to SPC aligned with the latest AIAG guidelines. It is designed for organisations that want to strengthen process control, reduce variation and make decisions based on reliable, data-driven insights. The course goes far beyond theory. Participants learn how to monitor process behaviour, evaluate capability, interpret control charts and react to early signs of instability long before nonconforming product is produced.

Training Program Highlights

SPC according to AIAG

1. Foundations of SPC and the Role of Data in Quality Management

Why statistical thinking is essential in modern quality systems (ISO 9001, IATF 16949, continuous improvement culture).

SPC in the context of quality tools and key international guidelines related to statistical methods.

Understanding the shift from product inspection to proactive process control.

How to define a process and how to read its natural behaviour.

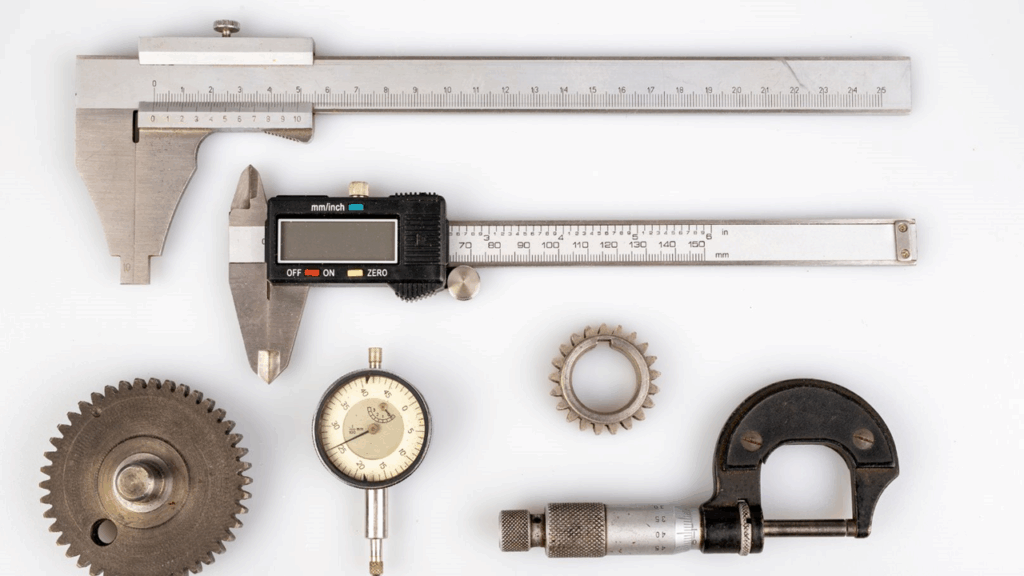

2. Process Variation – How to Understand, Measure and Interpret It

Types of variation: common vs special causes and the impact of disturbances on process stability.

Stable vs unstable processes – practical implications for decision-making.

Basic descriptive statistics: mean, median, dispersion, standard deviation, skewness, kurtosis.

Building and analysing histograms, empirical vs theoretical distributions.

Data normality – when it matters and how to verify it.

Hands-on exercises with real production datasets.

3. Process Capability and Machine Capability – Evaluating Performance

Short-term and long-term capability: interpretation of Cp, Cpk, Pp, Ppk.

Approaches used across the industry: AIAG, VDA and practices used by various OEMs.

Machine capability indices (Cm, Cmk) and their role in equipment qualification.

What to do when data are not normally distributed: transformations, percentile methods, alternative strategies.

Capability in the context of tolerance risk and customer expectations.

Practical calculation exercises.

4. Control Charts – The Core Tool for Monitoring and Improving Processes

How control charts work: three-sigma logic, chart construction, common interpretation pitfalls.

Conditions for proper chart setup and use – preliminary data, statistical assumptions, process specifics.

Control charts for variable data:

X̄–R chart,

X̄–S chart,

Median–Range chart,

Individuals–Moving Range chart.

Control charts for attribute data: p, np, c, u.

Detecting out-of-control signals: trends, runs, clustering, periodicity, boundary violations, zone rules.

How to select the right chart, sampling frequency and subgroup size.

Sensitivity of control charts – examples of specific control charts.

Case studies and interpretation exercises.

5. SPC and MSA – Why Measurement Quality Defines Process Control Quality

The relationship between measurement system errors and SPC results.

When a measurement system must be validated before SPC implementation.

Risks associated with poor measurement repeatability and reproducibility.

6. Wrap-Up and Practical Consultation Session

Recap of the essential SPC concepts.

Discussion of real participant challenges and production scenarios.

Recommendations for strengthening SPC in the organisation.

Training objectives

The purpose of this course is to equip participants with the knowledge and skills required to apply SPC effectively in a manufacturing environment. After the training, individuals will be able to analyse variation, assess process stability, select and interpret appropriate control charts and evaluate process capability according to AIAG expectations.

Target Audience

Quality Engineers and Process Engineers working with production data.

Quality Managers overseeing compliance with AIAG / IATF 16949.

Manufacturing Engineers involved in process optimisation.

Measurement and laboratory staff supporting SPC analysis.

Teams preparing for IATF audits or strengthening data-driven decisions.

Participant Benefits

After completing the training, participants will be able to:

understand variation and distinguish between random and assignable causes,

correctly apply descriptive statistics to production data,

choose and interpret the correct type of control chart,

recognise early instability signals and take preventive action,

calculate capability indices (Cp, Cpk, Pp, Ppk) and understand their meaning,

use SPC as a practical tool in daily decision-making.

Organizational Benefits

By implementing SPC correctly, the organisation will:

reduce scrap, rework and customer complaints through proactive detection of process shifts,

improve process consistency and long-term stability,

strengthen compliance with IATF 16949 and OEM customer requirements,

support a culture of data-driven decisions,

improve operational efficiency and manufacturing predictability.

Qualification confirmation

E-certificate

Training duration

2 days X 7 hours

Training price

In order to get an offer please send a request to: contact@qualitywise.pl.

Documents

Terms and conditions you will find here.

Contact

For additional questions, other training dates or a dedicated training offer for your company, please contact Qualitywise®!