Calibration of Length and Angle

Measuring Instruments

Can you fully trust your measuring instruments

when the quality of your product depends on their readings?

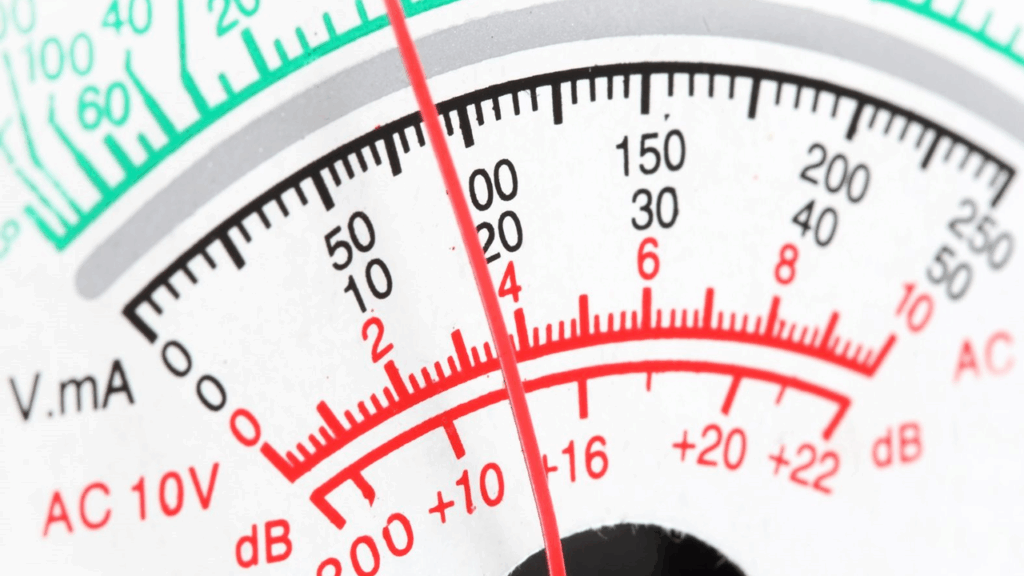

Calibration of measuring instruments is a set of activities aimed at determining the relationship between the indications of a measuring instrument and the values of reference standards. Its purpose is to ensure measurement traceability and to confirm that the instrument meets accuracy requirements and is suitable for its intended use.

Training Program Highlights

Calibration of Measuring Instruments

Standards and requirements: ISO 9001:2015, ISO 10012:2004, ISO/IEC 17025, ISO 14253 family, technical standards.

Metrological terminology: calibration, verification, validation, metrological characteristics.

Guidelines: international guidelines for calibration.

Measurement traceability: ensuring measurement consistency within the organization.

Technical issues: classification, design, use of measuring instruments; best practices.

Procedures and documentation: required procedures, instructions, and forms.

Measurement uncertainty: introduction to estimating uncertainty in calibration.

Calibration certificates: analysis and conformity assessment.

Requirements and selection of instruments: how to define requirements and select equipment for processes.

Managing measuring equipment in a modern enterprise:

Role in the quality system,

Planning and scheduling calibrations and periodic checks,

Identification and classification of equipment,

Documentation and traceability,

Internal vs. external calibration processes,

Computerized support for equipment management.

Laboratory organization: good metrology practice, personnel, competence, equipment.

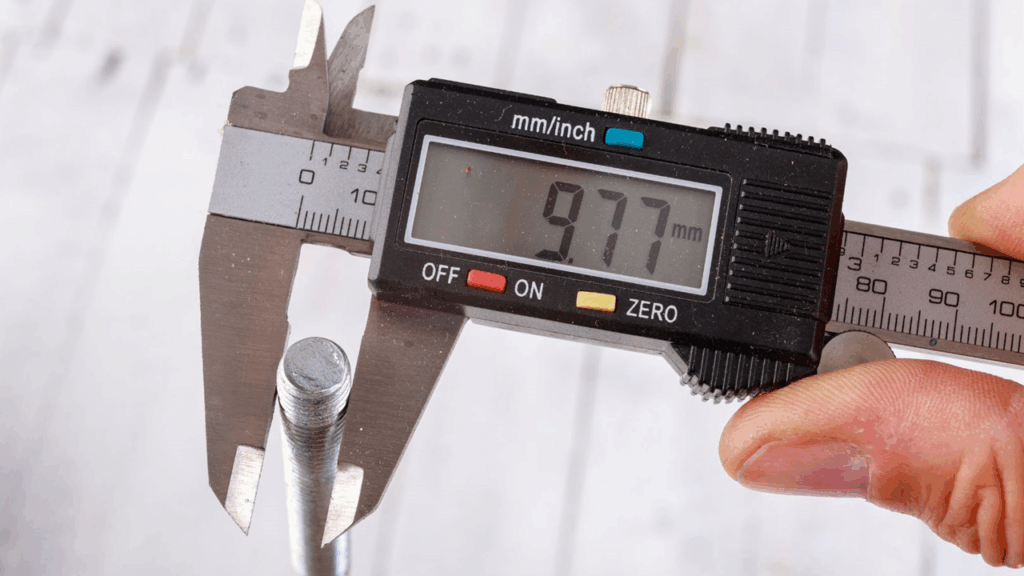

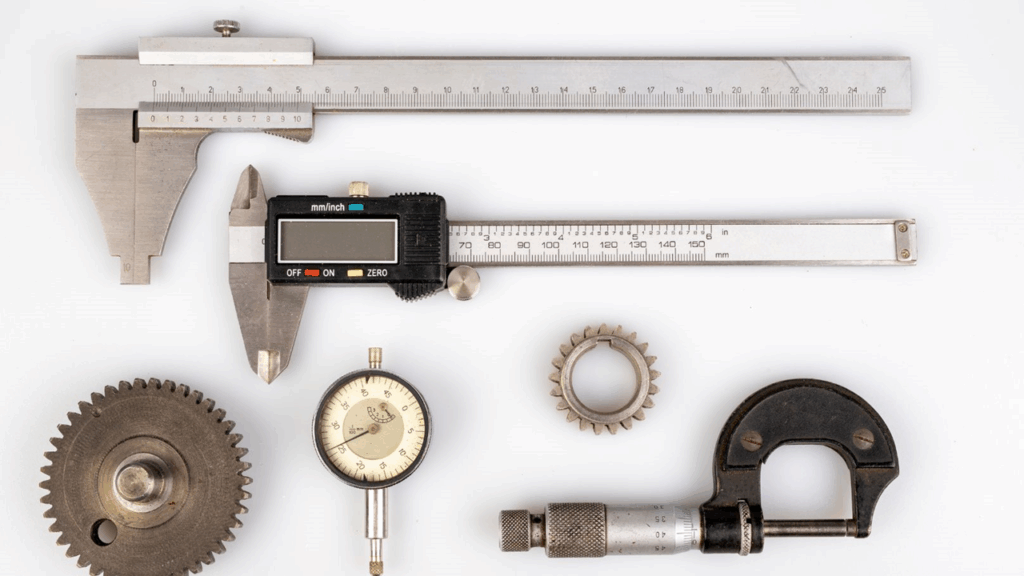

Practical training (for onsite courses): calibration and adjustment of instruments such as calipers, micrometers, dial gauges, squares, protractors, gauges (to be defined).

Training objectives

Understand basic normative requirements for calibration and equipment management.

Learn terminology and metrological characteristics of length and angle instruments.

Acquire practical skills in interpreting calibration certificates, conformity assessment, and instrument selection.

Gain hands-on experience in calibration and adjustment.

Target Audience

The training is intended for people responsible for measuring equipment management and measurement/control processes, especially:

Quality engineers and metrologists,

Laboratory staff in measurement and calibration,

Quality control and inspection personnel,

Internal auditors of quality systems.

Participant Benefits

Ability to interpret and use calibration certificates in practice.

Knowledge of conformity assessment and measurement uncertainty.

Broader understanding of design, use, and selection of instruments.

Hands-on calibration and adjustment practice.

Enhanced professional competence in metrology and quality systems.

Organizational Benefits

Reliable and traceable measurement results in production and quality control.

Compliance with ISO, IATF, and customer requirements.

Reduced risk of measurement errors, complaints, and defects.

Better preparation for certification audits and customer visits.

Organized and digitally supported equipment management system.

Qualification confirmation

E-certificate

Training duration

2 days x 8 hours

Due to the practical aspects,

on-site dedicated training is recommended.

Training price

In order to get an offer please send a request to: contact@qualitywise.pl.

Documents

Terms and conditions you will find here.

Contact

For additional questions, other training dates or a dedicated training offer for your company, please contact Qualitywise®!