MSA according to AIAG

Does your measurement system tell the truth, or do you silently accept errors that influence the entire production process?

MSA according to AIAG is one of the core quality tools widely applied in the automotive industry as well as other industrial sectors. The purpose of this training is to provide a practical understanding of methods for assessing measurement systems according to AIAG guidelines – from classical R&R studies, through linearity and stability analysis, to attribute system evaluations. During the course, participants will not only learn the theory but will also practice step by step how to evaluate the capability of measurement systems, interpret results, and apply them in practice.

Training Program Highlights

MSA according to AIAG

1. Introduction to MSA

The role of measurement system analysis in quality management.

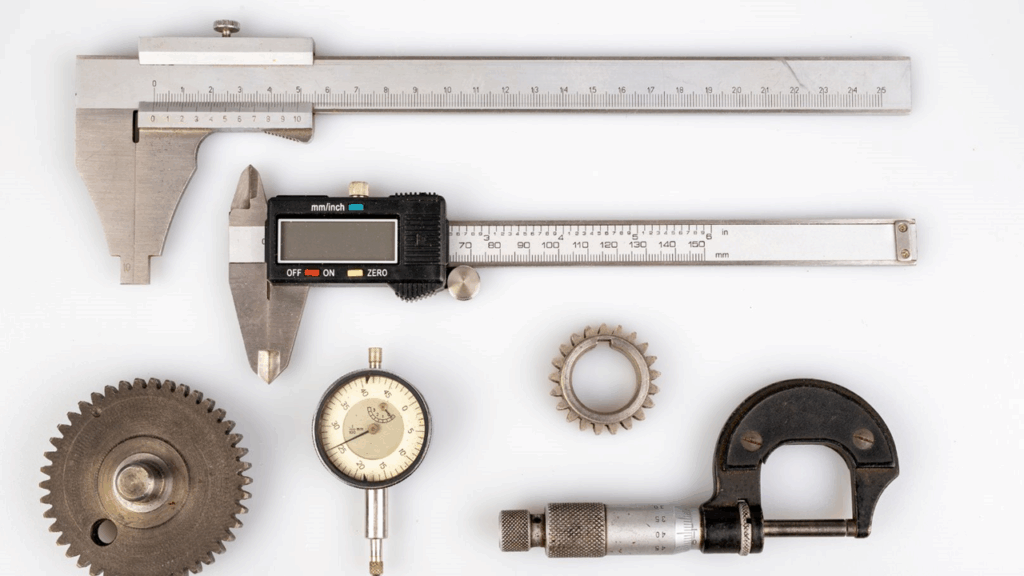

Basic terminology and definitions: measurement, error, measurement uncertainty, measurement system, measurement process.

2. Sources of Variation in Measurement Systems

Equipment variation (EV).

Appraiser variation (AV).

Part-to-part variation (PV).

Total variation (TV).

3. Measurement System Discrimination, Accuracy, and Precision

Key concepts explained.

Discrimination: scale discrimination, statistical discrimination (number of distinct categories – ndc).

Accuracy: systematic error, linearity, stability.

Precision: repeatability, reproducibility, interactions.

Operating characteristic curve of the measurement system.

Criteria for assessing the suitability of a measurement system for monitoring processes/products.

4. Qualification of Measurement Systems with Respect to Accuracy

Methods of evaluating systematic error.

Linearity and stability analysis.

Practical examples and exercises.

5. Qualification of Measurement Systems with Respect to Precision

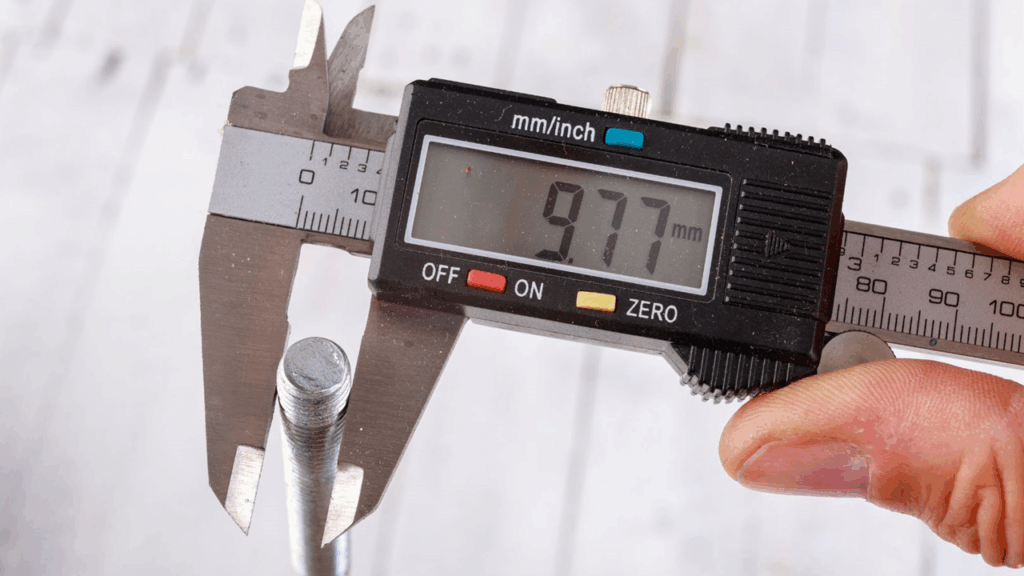

Methods for evaluating repeatability and reproducibility (R&R):

Range method (R),

Average and range method (ARM),

Analysis of variance (ANOVA) – considering both possible and impossible repeated measurements on one part.

Measurement system capability: calculation and interpretation of Cg and Cgk indices.

Short introduction to measurement uncertainty budgets.

Practical examples and exercises.

6. MSA for Attribute (Qualitative) Assessment

Criteria for evaluating measurement systems in attribute assessments.

Qualification methods: short method, long method, analytical method, signal analysis.

Long method (Attribute R&R): effectiveness, miss rate, false alarm.

Agreement analysis: operator/operator, operator/reference – calculation and interpretation of Cohen’s kappa coefficient.

Practical examples and exercises.

Training objectives

The training aims to enable participants to:

-

identify sources of variation in measurement systems,

-

perform R&R studies and evaluate system capability,

-

apply qualification methods for both variable and attribute measurement systems,

-

correctly interpret MSA results and make decisions on measurement system suitability.

Target Audience

-

Quality engineers, process and production engineers,

-

Employees of metrology, laboratory, and quality control departments,

-

Internal and external auditors of quality management systems,

-

Anyone responsible for supervision and analysis of measurement data.

Participant Benefits

-

Gain knowledge and skills necessary to conduct MSA studies independently.

-

Learn to apply in practice various methods of measurement system qualification (R&R, ANOVA, attribute analysis).

-

Be able to assess the suitability of a measurement system for monitoring processes and products.

-

Work with practical examples and exercises on data analysis.

Organizational Benefits

-

Increased reliability of measurement results and decisions based on them.

-

Better compliance with customer requirements and industry standards (IATF 16949, AIAG).

-

Reduced risk of incorrect quality assessments and unnecessary costs related to complaints.

-

Enhanced team competence in applying quality tools and supervising measuring equipment.

Qualification confirmation

E-certificate

Training duration

2 days x 8 hours

Training price

In order to get an offer please send a request to: contact@qualitywise.pl.

Documents

Terms and conditions you will find here.

Contact

For additional questions, other training dates or a dedicated training offer for your company, please contact Qualitywise®!