Management of Measuring Equipment

in a Modern Organization

Have you ever wondered whether your measuring equipment management system truly guarantees reliable results and full compliance with ISO requirements?

Effective management of measuring equipment is a cornerstone of reliable results and process consistency in both production and service organizations. This training combines theory with practice – from discussing legal and normative requirements, through methods of identification, classification, and control of equipment, to the practical application of measurement uncertainty. Participants will also learn how to apply IT tools to support measurement management and how to prepare for internal and external audits.

Training Program Highlights

Legal requirements, directives, and standards (ISO 9001:2015, ISO 10012, ISO/IEC 17025, etc.)

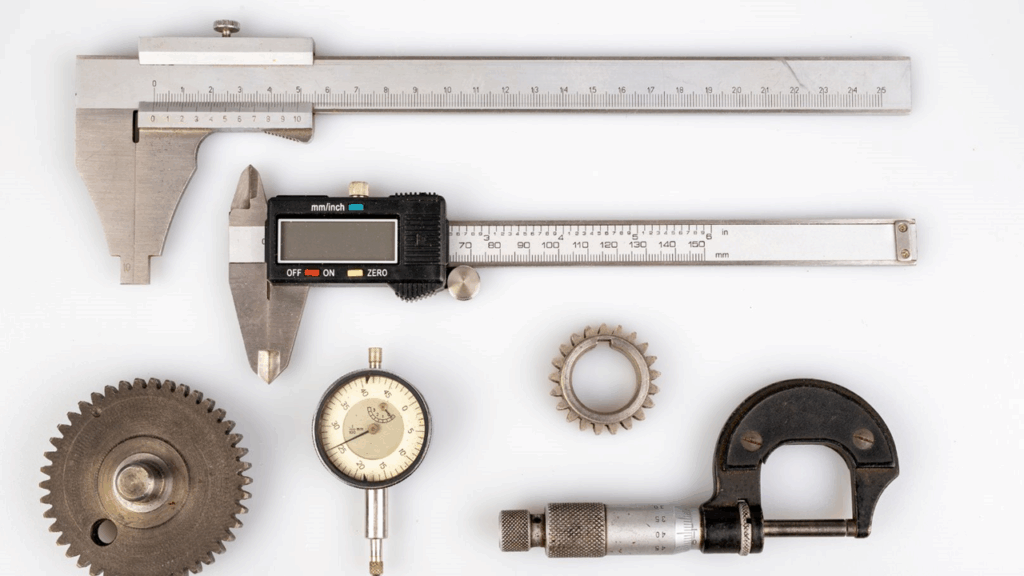

Terminology and concepts used in measurement equipment management

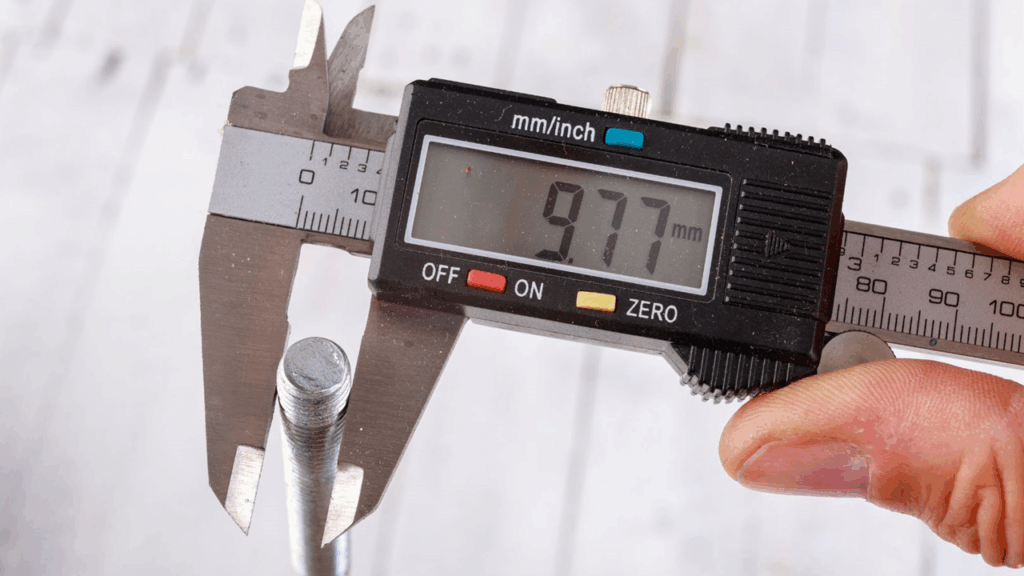

Identification and classification of measuring equipment

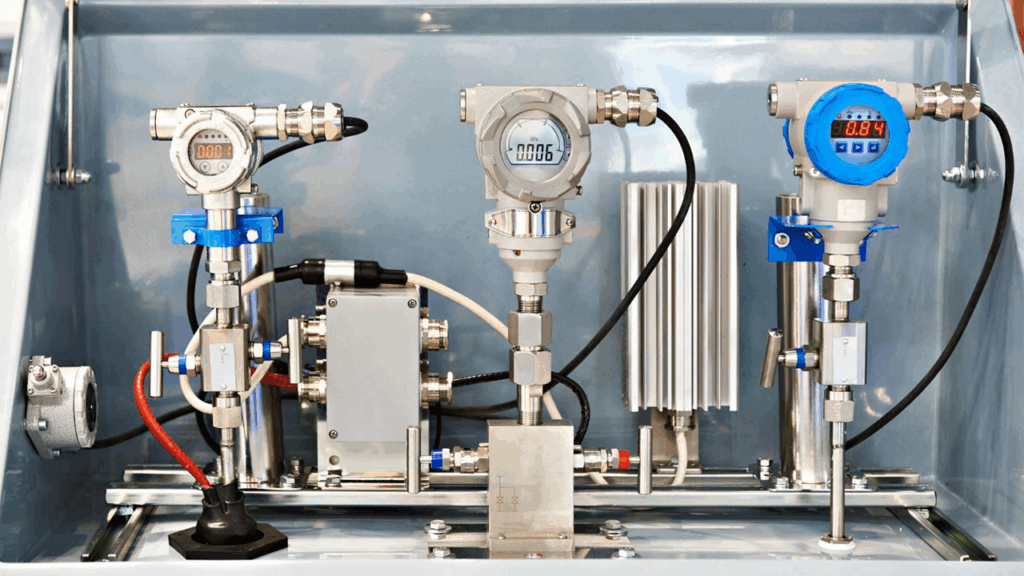

Principles of ensuring measurement traceability

Organization of supervision over equipment: schedules, responsibilities, documentation, calibration

The role of measuring equipment management in the quality management system

Organization of inspection processes: internal vs. external service providers

IT support for measurement equipment management

Conformity assessment of measuring instruments with specifications

Understanding and practical application of measurement uncertainty

Auditing measurement management systems

Training objectives

The aim of this training is to prepare participants for effective and compliant management of measuring equipment in line with legal requirements and international standards. Participants will gain knowledge on how to implement a consistent process of supervision over measuring instruments, how to interpret normative requirements, and how to ensure reliability and repeatability of measurement results within their organization.

Target Audience

This training is designed for professionals responsible for measurement equipment supervision, quality engineers, technologists, laboratory staff, and quality management representatives.

Participant Benefits

Understanding of normative and legal requirements for measurement equipment management

Ability to implement a consistent system for supervision and documentation

Knowledge of methods for conformity assessment and use of measurement uncertainty in practice

Preparation for audits and effective demonstration of system compliance

Organizational Benefits

Increased reliability and consistency of measurement results in production and laboratory processes

Reduced risk of complaints and errors caused by inadequate measurement control

Cost optimization through better organization of calibration, verification, and documentation processes

Improved employee awareness and higher quality of measurement process management

Qualification confirmation

E-certificate

Training duration

1 day x 8 hours

Training price

In order to get an offer please send a request to: contact@qualitywise.pl.

Documents

Terms and conditions you will find here.

Contact

For additional questions, other training dates or a dedicated training offer for your company, please contact Qualitywise®!